Product

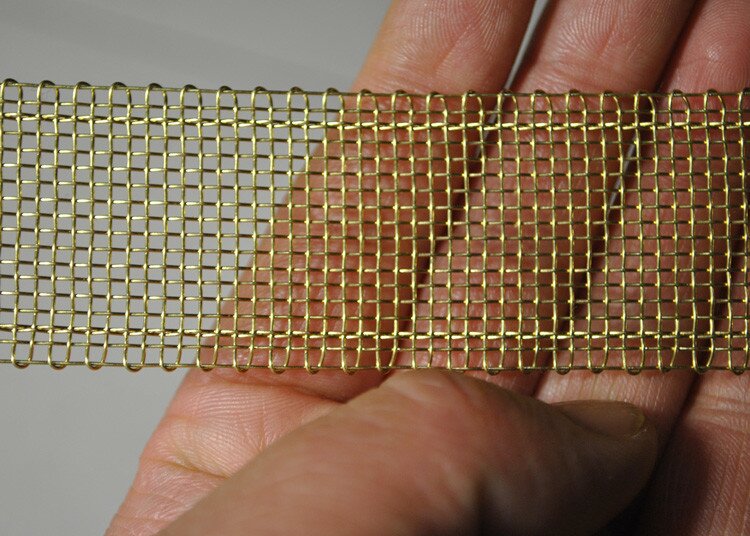

World Copper Wire Mesh Supplier

Basic Information

Due to the excellent conductive property of copper, Radio Frequency Interference Shielding, Grounding Grids and Lighting Arrestor Elements commonly incorporate copper wire cloth. Copper wire mesh applications may be limited due to its low tensile strength, poor resistance to abrasion and common acids.

The chemical composition of copper wire mesh is 99.9% copper, it is a soft and malleable material. Copper wire mesh is available in various mesh counts to produce specific opening sizes to meet our industrial users' requirements.

Popular industries and applications of Brass Wire Mesh

- Energy storage

- Electric heaters

- Pest control fumigation

- Tactical shelters & modular containers

- Robotics & power automation

- Gamma irradiators

- Health, body and mind enrichment

- Space program initiatives (NASA)

- Metal smithing & bookbinding

- Air & liquid filtration and separation

Application of Copper Wire Mesh

Copper wire mesh is ductile, malleable and has high thermal and electrical conductivity. Because of these unique characteristics, it is often used as RFI shielding, in Faraday Cages, in roofing and in countless electrical-based applications. Without a doubt, copper wire mesh is critical to industry, and as such, it is used in general industrial applications. Not surprisingly, copper mesh is often at the center of technological advancements in a broad range of fields.

Copper wire mesh's unique color makes it a very popular option for many different types of users, including designers, artists, architects and home owners. Home owners and designers opt for copper woven wire mesh for residential projects including gutter guards, soffit screens, insect screen, and fireplace screen. Sculptors, wood workers, metal artisans and architects also find copper mesh to be an excellent option because of its remarkable dark amber-red color and its broad appeal to a wide audience.

Where can copper woven mesh be used?

- RFI/EMI/RF Shielding

- Electronic information security

- Faraday Cages

- Power generation

- Insect Screens

- Outer space exploration and research

- Fireplace Screen

- Electronic security

Brass Wire Mesh

Brass alloys - standard chemical composition

|

230 Red Brass |

85% Copper 15% Zinc |

|

240 Low Brass |

80% Copper 20% Zinc |

|

260 High Brass |

70% Copper 30% Zinc |

|

270 Yellow brass |

65% Copper 35% Zinc |

|

280 Muntz Metal |

60% Copper 40% Zinc |

Yellow brass is the most popular brass alloy for wire cloth screens. Brass(typically 80% copper, 20% zinc) has much better abrasion resistance, better corrosion resistance and lower electrical conductivity when compared to copper. The tensile property of brass wire mesh is higher than those of copper with some sacrifice in formability . Brass will usually maintain its bright finish over time, will not darken with age as does copper.

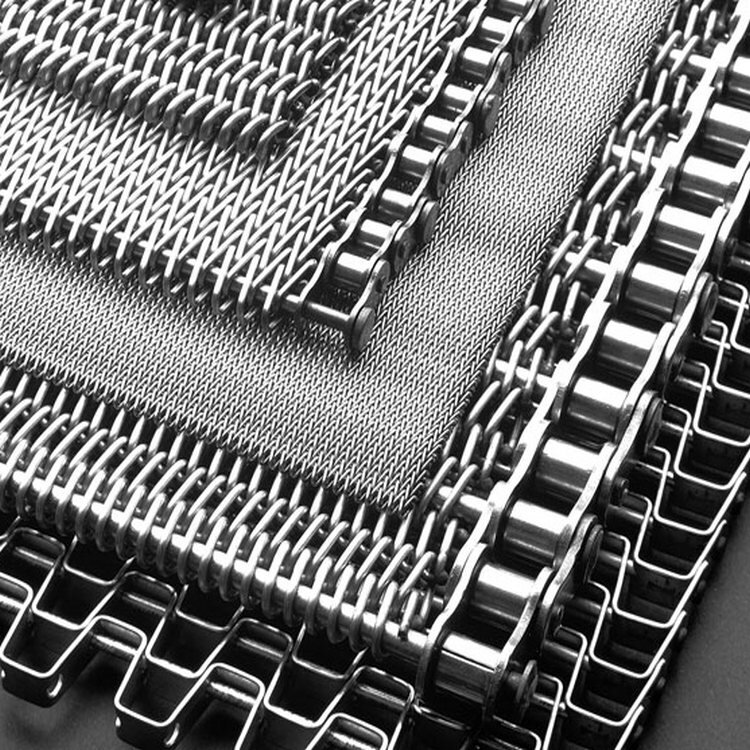

Bronze Wire Mesh

Phosphor Bronze, Cu 94 %, Sn 4.75%, P .25%

Phosphorus bronze wire mesh is formed of Copper, Tin and Phosphorous (Cu: 94%, Sn: 4.75%, and P: .25%). Phosphor bronze wire mesh, as it is commonly called, exhibits physical and anti-corrosive properties slightly superior to those of copper and zinc alloys. Phosphorus bronze wire mesh is typically found in the finer meshes (100 x 100 Mesh and finer). This material has great strength, durability and ductility. It is also resistant to common corrosive agents.

Part specs of bronze wire mesh

|

Mesh/In |

Wire Dia.(In) |

Opening(In) |

Open Area(%) |

Weave Type |

Width |

|

2 |

0.063 |

0.437 |

76 |

PSW |

36" |

|

4 |

0.047 |

0.203 |

65 |

PSW |

40" |

|

8 |

0.028 |

0.097 |

60 |

PSW |

36" |

|

16 |

0.018 |

0.044 |

50 |

PSW |

36" |

|

18 X 14 |

0.011 |

0.044 X 0.06 |

67 |

PW |

48" |

|

18 X 14 |

0.011 |

0.044 X 0.06 |

67 |

PW |

60" |

|

20 |

0.016 |

0.034 |

46 |

PSW |

36" |

|

30 |

0.012 |

0.021 |

40 |

PSW |

40" |

|

40 |

0.01 |

0.015 |

36 |

PSW |

36" |

|

50 |

0.009 |

0.011 |

30 |

PSW |

36" |

|

100 |

0.0045 |

0.0055 |

30 |

PSW |

40" |

|

150 |

0.0026 |

0.004 |

37 |

PSW |

36" |

|

200 |

0.0021 |

0.0029 |

33 |

PSW |

36" |

|

250 |

0.0016 |

0.0024 |

36 |

PSW |

40" |

|

325 |

0.0014 |

0.0016 |

29 |

TSW |

36" |

|

400 |

0.00098 |

0.00152 |

36 |

PSW |

39.4" |

|

Type |

Red Copper Wire Mesh |

Brass Wire Mesh |

Phosphor |

Tinned Copper Wire Mesh |

|

Materials |

99.99% pure copper wire |

H65 wire (65%Cu-35%Zn ) |

Tin bronze wire |

Tinned copper wire |

|

Mesh Count |

2-300 mesh |

2-250 mesh |

2-500 mesh |

2-100 mesh |

|

Weave Type |

Plain/Twill Weave and Dutch Weave | |||

|

Common Size |

Width 0.03m-3m; Length 30m/roll, Can also be customized. |

|||

|

Common Feature |

Nonmagnetic, good ductility , Wear resistance, |

|||

|

Special Features |

Sound insulation |

Maintain its bright finish over time |

Great strength, durability and ductility |

High temperature resistance, anti-aging,and long service life |

|

Common Applications |

EMI/RFI shielding |

Apply to Newspaper/ Typing/chinaware printing; Smoking screen; |

Apply to |

Engine filter for cars, |